316L Stainless Steel Plate

- Commodity name: 316L Stainless Steel Plate

Keyword:

316L Stainless Steel Plate

- PRODUCT DESCRIPTION

-

316L Stainless Steel Plate Description

316L stainless steel is an austenitic stainless steel metal alloy that contains nickel and molybdenum, making it corrosion resistant. 316L is a 316 low carbon grade. This grade is not affected by sensitization (grain boundary carbide precipitation). It is often used for large-gauge welded parts (approximately over 6mm). 316L stainless steel has higher creep, fracture stress and tensile strength than chromium nickel austenitic stainless steel at high temperature.

Product ParametersProduct Name

316L Stainless Steel Plate

Type

Plate

Thickness

0.3mm-200mm

Length

2000mm, 2438mm, 3000mm, 5800mm, 6000mm, 12000mm, etc.

Width

40mm-600mm, 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc.

Standard

ASTM, AISI, JIS, GB, DIN, EN, etc.

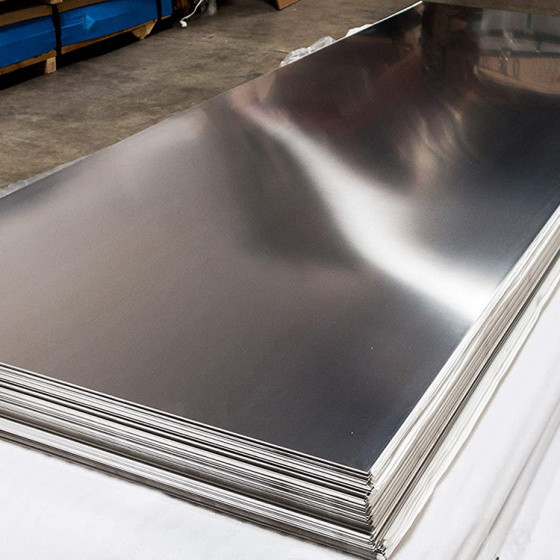

Surface

BA, 2B, NO.1, NO.4, 4K, HL, 8K, etc.

Scope of Application

Widely used in high temperature and electrical industry, medical equipment construction, chemical, food industry, agriculture and ship parts, food and beverage packaging,

Kitchen supplies, trains, airplanes, conveyor belts, vehicles, bolts, nuts, springs and screens, etc.

Certificate

ISO, SGS, BV, etc.

Production Technology

Hot Rolling, Cold Rolling

Edge Processing

Edging, Trimming

Chemical Composition

C

Si

Mn

Cr

Ni

S

P

Mo

≤ 0.03

≤1.0

≤ 2.0

16.0~18.0

10.0~14.0

≤ 0.03

≤ 0.045

2.0~3.0

Mechanical Properties

Tensile Strength Kb (MPa)

Yield Strength σ0.2 (MPa)

Elongation D5 (%)

Hardness

≥480

≥177

≥ 40

≤ 187HB;≤ 90HRB;≤ 200HV

Physical Performance

Density(g/cm³)

Modulus of Elasticity(Gpa)

Coefficient of Thermal Expansion(10-6/°C)

Coefficient of Thermal Conductivity(W/m*K)

Resistivity(ΜΩ. cm)

7.99

193

16.0

16.2

74

Surface Selection

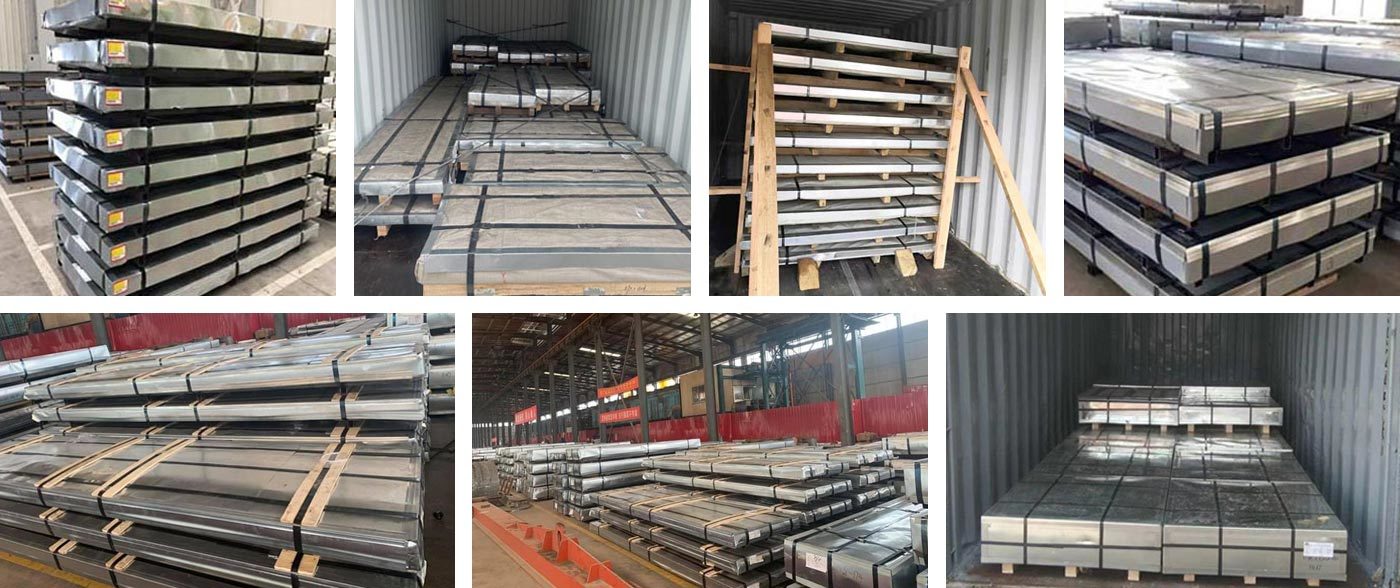

Packing and delivery

Our company adheres to the principle of reputation first and small profits but quick turnover, and expands the market with high-quality services and flexible business models. Our product quality, price, service and reputation remain the same as before. With the strong assistance and support of new and old customers, we continue to grow and become a professional steel export manufacturer.

Application areas

Its products are suitable for various fields such as automobiles, motorcycles, power, machinery, hydraulic accessories, bearings, pneumatic components, oil cylinders, coal mines, conveyors, boiler equipment, pipelines, engineering, etc. Our company has 5 perforation units, 30 precision rolling machines, and 6 cold drawing machines.

Factory appearance

It is a specialized manufacturer and seller of carbon steel, steel bars, stainless steel, galvanized, hot-rolled seamless steel pipes, precision seamless steel pipes, cold drawn seamless steel pipes, alloy pipes, special-shaped pipes, etc.

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products